A large machete knife can be used both in the kitchen and on a hike (for example, to clear a passage or to "cut" branches for a fire).

A popular material for the manufacture of machetes and other knives is a car spring, which is made of spring-spring steel grade 65G.

You can also use machine blades for mechanical saws made of high-speed steel grade P6M5 (this is the so-called rapid).

The main stages of work

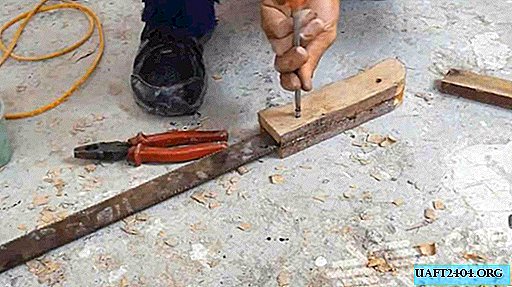

First of all, on the workpiece, you need to make small slots (on both sides) along the entire length. After that, the master grinds the blade.

In the next step, you will need to make a handle for a machete knife. For this, the master uses two blanks from the board, which must be sawed to size.

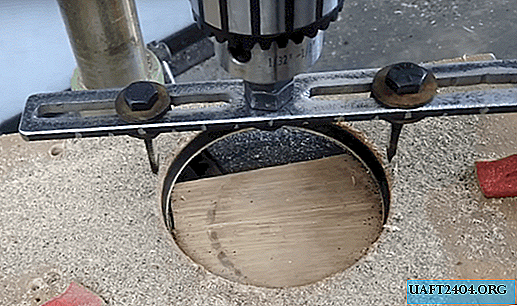

We drill holes in the metal workpiece and the halves of the handle, then glue them to the tail of the machete knife. For bonding parts, you can use epoxy glue.

Then the author proceeds to machining the handle. On the sides you need to make grooves into which then metal plates are inserted.

The final touch is the polishing of the metal and the final sharpening of the blade. This stage is one of the most laborious. The wooden handle can be varnished or soaked in mineral oil.

Details on how to make a large machete knife with your own hands can be found in the video on our website.