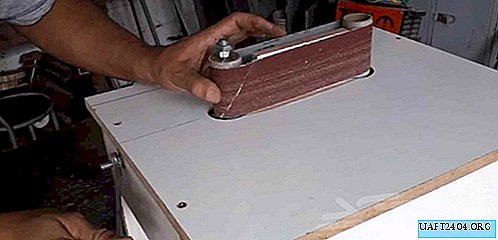

With the help of a homemade nozzle on an electric drill, you can clean the surface of the metal from rust in hard to reach places. For example, inside steel pipes and landing "nests" for bearings.

For the manufacture of this nozzle you will need a piece of a metal tube, a stud, nuts to it, as well as a cable in transparent PVC insulation.

First you need to cut a piece of metal tube 8 cm long. In this case, the author decided to use a piece of the gander for the mixer. You also need to cut a piece of hairpin, but a little longer - about 15 cm.

The process of manufacturing a nozzle on an electric drill

A segment of the stud must be inserted into the tube and fixed on both sides with nuts. Next, the master marks the location of future holes with a marker and makes the “marks” the punch in 1 cm increments. After marking, you can start drilling.

In total, it will be necessary to drill four rows of holes (eight holes in each row). Moreover, note that in the perpendicular rows the holes should be drilled a little with an offset relative to each other.

At the last stage, you need to cut pieces of cable with transparent corrugated insulation with a length of 8 centimeters. These segments are then inserted into the drilled holes in the tube and stud.

In detail about how to make a nozzle on a drill for cleaning metal in hard-to-reach places, you can see in the video on the site.