If you are just starting to learn the basics of metal forging, and want to do something with your own hands, try to start by processing ordinary fittings.

From this publicly available building material, for example, a spoon and a knife can be made. It is clear that such cutlery is not suitable for proper use. However, as decorative elements such products will look quite appropriate.

First of all, it is necessary to cut the reinforcement into blanks of the desired length. Since the fork and knife are not very long, for the convenience of processing, the master welds additional pieces of reinforcement to the workpieces.

The main stages of work

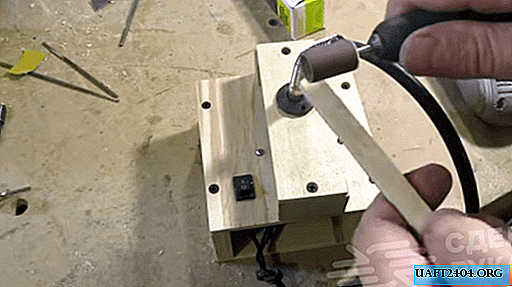

Next, the workpiece from the reinforcement must be heated to red. In this case, the master uses a do-it-yourself gas horn. The design is quite primitive, but most importantly, everything works.

And first of all, the master makes a fork. To do this, he first flattenes one end of the reinforcement, and then makes a slight bend on the anvil horn, giving the workpiece the classic shape of a table fork.

After that, the master processes the workpiece on a grinding machine. Using a grinder makes teeth. Then it will be necessary to tidy up a little the handle of a fork. To do this, the master decided to use a cord brush.

At the last stage of work, a table knife is made. Moreover, its production will require less time. Details on how to make a tablespoon and knife from ordinary fittings can be found in the video on the website.