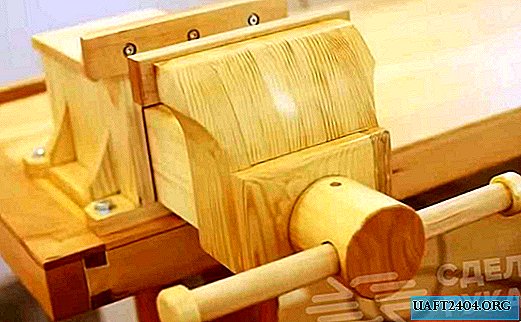

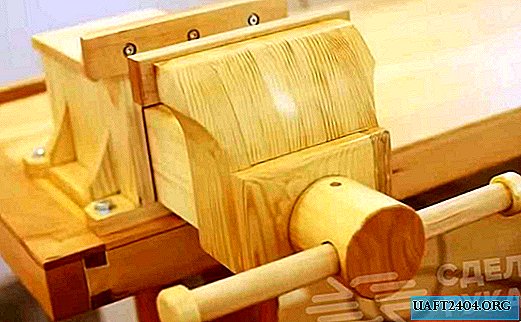

Classical bench vices, which are present in almost any workshop, are made of metal. But if you wish, you can make a "lite" option - wooden bench vise.

This homemade product, in addition to performing the main function (fixing blanks), will also become an original decoration of the interior. At the same time, collecting it is not as difficult as it might seem at first glance.

The first step is to cut off the steel screw of the desired length. Then, from a piece of wood, the master makes a seat under it. It was possible, of course, to make a completely wooden screw, but this is a very time-consuming process, and therefore it is easier to do with a metal one.

The main stages of work

At the next stage, the master cuts the blanks from the board, from which he then collects the bed for the bench vice. Everything is done according to a drawing drawn in advance, and therefore work is fast.

Then again, it will be necessary to cut the workpieces and glue from them the upper part of the vice, which is glued to the bed. By the way, plywood can also be used instead of boards - it will turn out no worse.

At the last stage of work, the movable part of the vise is made, and it will also be necessary to make and fasten the clamping jaws in their places. Then the final assembly is performed. The finished product can be varnished, and preferably mineral oil.

For details on how to make a wooden bench vise for a workshop with your own hands, see the video on the site.