When machining small parts (for example, grinding or cutting metal with a grinder, drilling holes with an electric drill or a drilling machine, cleaning the surface with a brush, etc.), it is not always convenient to hold the workpieces in your hands. Therefore, when performing such operations, you can use a homemade hand clamp.

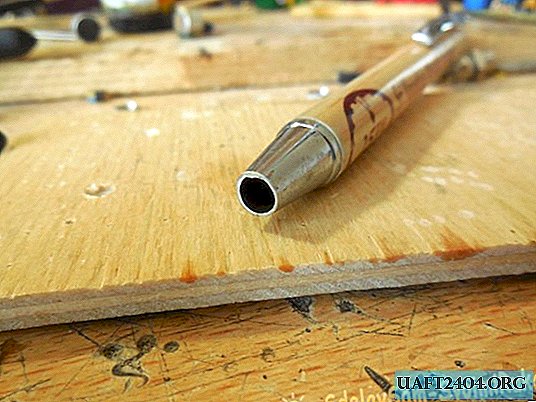

For the manufacture of the tool, simple and affordable materials will be required: 3 identical pieces of a steel plate 6x3 cm, a piece of round timber 10-15 cm long, as well as rectangular metal scraps that will be used as hand clamp clamping jaws.

The main stages of work

First of all, you need to drill two identical holes in each of the three plates, and then put one plate on a steel rod and weld.

It is necessary to weld the clamping jaws of the manual clamp from the scraps of sheet metal to the two remaining steel plates (pieces of file can also be used for this).

A handle must be welded to the central plate, which is connected to the round timber - it can be made independently or removed from some mechanism. To weld the handle, you must first make a small groove in the plate using a grinder or on a band saw.

At the last stage of work, it remains only to clean the welding spots with a grinding wheel and assemble the manual clamp from the prepared components. We put two plates with clamping jaws on a steel rod and fix them with a bolt with washer and nut.

For convenience, a screw can be welded to the head of the bolt. For more information on the manufacture and assembly of this homemade product, see the video on the site.