In the workshop, we always have a lot of files (rasps, files) and fragments from them of different sizes and purposes. Some did not have pens initially, others quickly broke down or would soon break, while others had pens that were completely inconvenient to use.

Instead of making or often repairing a handle for each file, you can make one - universal. For work, we need: a strong metal sheet with a thickness of about 5 mm, a ruler, marker, grinder, drill, welding machine, screws, washer, nuts.

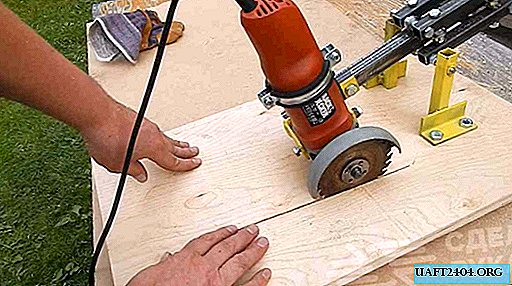

On a metal sheet we draw two figures. The first is the letter "T". The "upper crossbeam" is 9 cm long, 3 cm wide. The "legs" are 6 cm long, 3 cm wide. The second figure is a rectangle 9 cm long and 3 cm wide. The dimensions are approximate. Cut out these forms with a grinder. We process the sharp edges of the products so that there are no burrs, slightly round them.

The main stages of work

Combine the rectangular with the same size part of the T-shaped figure. We drill three holes along the edges with a drill. For the handle, we take a screw with a length of about 12 cm. Calculate the size based on the size of your gloved hand, so that it is convenient to hold.

Insert the screw into the hole on the "leg" of the T-shaped figure at an angle of 45 degrees. We weld it and cut off the head with a grinder. Cut a piece of polypropylene pipe and put on the screw. Put the washer on top and screw the nut, pressing the pipe.

To complete the construction, you will need two short screws and two nuts that will tighten the T-shaped and rectangular figures with a file firmly fixed between them.

So, in a few minutes we made a universal handle for files. It is durable, comfortable and will serve you for many years. See the detailed manufacturing process in the video on the website.