A drop in compression in the engine cylinders not only indicates wear on the pistons or rings, but is also one of the main reasons for the sharp increase in fuel consumption. Therefore, for the purpose of prevention, car owners must regularly check the technical condition of the engine (gasoline or diesel).

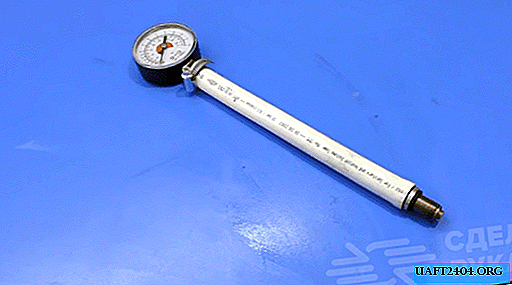

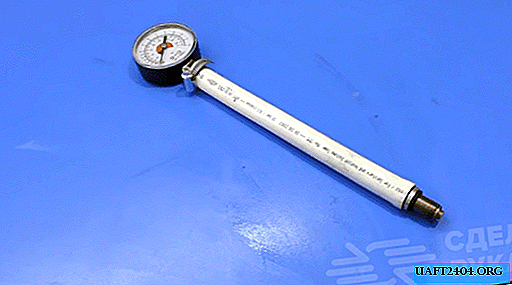

In order not to overpay for this service in the service center, you can make a measuring device - a compressometer with your own hands from an old spark plug. To assemble a home-made device for measuring compression, you will also need a manometer, a nipple and a piece of metal-plastic tube.

The main stages of work

First of all, with the help of a grinder, it is necessary to cut off the rolling of the core of the old spark plug. We remove the core, after which we clamp the metal case in a vice or with a clamp, and cut off the “tongue” (side electrode).

You also need to remove the washer. If in a good way the puck does not want to unscrew, then this problem can be solved by a more radical method - using an angle grinder with a cutting disc.

By the way, the insulator of the old spark plug can also be used for the manufacture of various homemade products and appliances. However, the insulator is a rather fragile material, so you need to remove it very carefully. How to do this correctly, you can find in this review.

Grind the edges of the nut on an emery. Then we drill the main hole with a drill with a diameter of 9.5 mm. After that, we cut off the back of the nipple, and install the "stub" inside the metal body of the spark plug, after lubricating it with an ordinary soap solution.

The resulting workpiece must be pressed into a piece of metal-plastic pipe with a length of about 20 cm. And on the other side of the tube, a manometer is attached with a clamp. See the video on the site for the process of manufacturing a compressor.