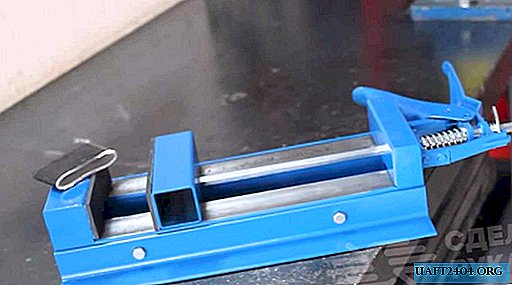

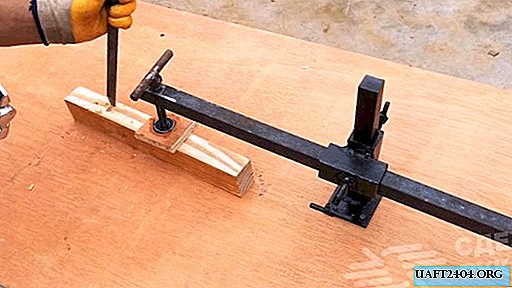

Sometimes when gluing or machining wooden blanks, it is not possible to use a vice and clamps. In this case, you can use the universal home-made device - a vertical rack with a clip. With such a simple design, it is possible to reliably press workpieces of different thicknesses to the table surface.

The main stages of work

First of all, it is necessary to weld together two corners of 45x45 mm in order to get a square profile (in principle, you can use a thick-walled profile pipe with side dimensions of 45x45 mm). The resulting workpiece is cut in half - into two identical parts.

Then you will need a steel plate of a rectangular shape (it is better to take a square one so that the area of the support is larger), in which it will be necessary to drill holes for fasteners. In the center of the base we weld a vertical stand from a steel square with side dimensions of 40x40 mm.

Two pieces of a square profile from the corner are welded perpendicular to each other, and then put on a vertical rack. We fix the second steel square horizontally. In profiles welded from a corner, we drill holes for fixing bolts or studs with a screwdriver. At the last stage of work, we weld the third hairpin with the pressure nickel to the horizontal square.

The result is a home-made vertical stand with a clip for fixing wooden workpieces on a desktop or workbench. For a detailed assembly process, see the video on the site.