Cheap Chinese clamps are only good because they are inexpensive. For the rest, it is often a poor-quality tool that very quickly becomes unusable. If possible, it is better to make a homemade clamp. But not some simple, but eccentric.

Of the basic materials for this homemade product, sheet metal blanks will be required. The eccentric itself can be made of steel round timber with a diameter of 3.5-4 cm.

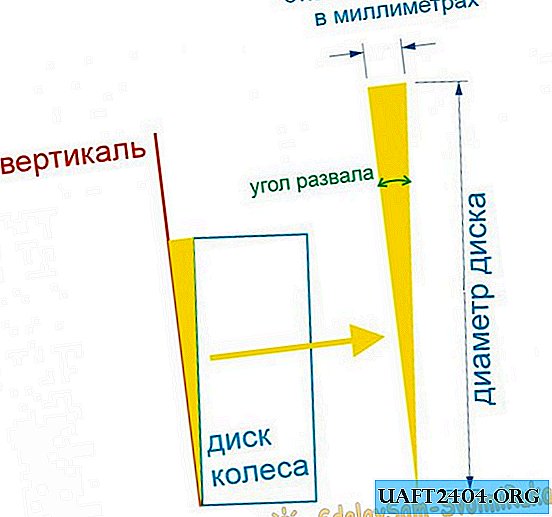

In order for the round piece to become an eccentric, it will be necessary to drill a through hole in it with an offset of about 3-5 mm from the center. To do this, the author clamps the workpiece in a vise, makes a “mark” with a punch and drills a hole.

The main stages of work

From two strips of metal 6 mm thick (long and short) it is necessary to weld a frame of a L-shaped form for a clamp. Then, from the scraps of the steel plate, it will be necessary to weld the movable "carriage", which will move along the rack of the frame.

Please note that the play should be small. Then you will need strips of metal (2 pieces) in which you need to drill holes. Add a long bolt, an eccentric and a welded “carriage”, and put everything in a heap.

At the last stage, it remains only to make a clamping "paw" from the profile pipe 30 * 30 mm, which is mounted next to the eccentric.

For details on how to make an eccentric clamp from metal, we recommend that you look in the video on the site.